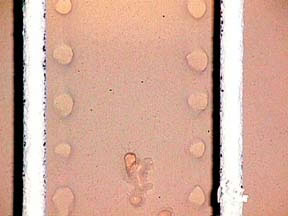

(Photos above) This series first shows a problem with demineralizer distributon. Note the uneven distribution pattern from existing hub and lateral. AWTS retrofit with header& lateral system minimizes void, increasing regeneration efficiencies all around. Now note the even distribution pattern in resin.

AWTS proprietary nozzle used in distributor design (above) saves companies money in restored equipment and reduced chemical usage. Your money belongs in your hands, not down the drain.

Read full story at right.

(Photos below) Poorly designed existing and failing internals were replaced with AWTS proprietary screen (nozzle) design (patent applied for).

Failing distributors (above) replaced with improved retrofit proprietary design screen/nozzle (immediately below).

|

|

(Photos) The AWTS proprietary resin trap is another product that has saved companies money. It is designed to stop loss of filter media or resin in process control vessels. (See story at right >)

AWTS resin trap consists of housing of SS or acrylic construction (SS shown on left) and strainer baskets of various construction material (SS shown top right), installed in the service outlet or in the backwash outlet piping.

Call Advanced Water Treatment Technologies Services for your next project:

(972) 733-4404

Big Problems, Small Solutions

(Scroll down the page to see the whole story.)

"Ion-Exchange Demineralizers, Big Problems, Small Solutions" is the title of a paper written by Ken Pandya, president of AWTS Inc., presented to the 58th Annual Meeting, International Water Conference, Pittsburgh, Pennsylvania, USA. That work has become a reference work for owners and consultants working with rehabilitation of Ion-Exchange Demineralizers.

Excerpt from the Introduction: "There are thousands of demineralizers around the world that provide high purity for boilers, turbines, industrial and commercial processes. Many of these demineralizers are over 25 years old. In almost all cases, raw water composition, flow rates, daily throughput requirements and treated water quality have changed. Today, these demineralizers are working harder than ever. As expected, the owners are experiencing substantial increase in regeneration chemical costs, increase in waste water volumes, and O&M costs. Such frustrated owners faced with the task of updating their systems often consider retrofitting or replacing the entire system with newer technologies, which may cost even more in the long run." Download PDF of Article.

Conclusion: The article considers several case studies, showing that most system failures are due to improper use and application of resins, variation in flow rates, wrong regeneration techniques, and most often worn distributors that degrade performance, all of which can be remedied with cost effective retrofit replacement of old distributor systems and re-training of the O&M crew. See and read the articles

AWTS proprietary products solve old problems with improved design.

(See photos and captions at left.)

AWTS offers owners and plant managers a viable alternative to competing, yet failed designs that are still being used in the industry. First-hand experience in the many rehabilitations performed by AWTS has uncovered again and again, exactly where and why a system fails. It is often small yet critical components, such as distributor nozzles, faulty distribution design, or omission of a simple component such as a resin trap that cause capacity to fall below specifications, water quality, and very expensive systems to deteriorate because of a very inexpensive solution.

AWTS Proprietary Screen/Nozzle Design saves companies money in restored equipment and reduced chemical usage. Your money belongs in your hands, not down the drain.

- Revolutionary under drain nozzle design

- Minimizes dead legs and maximizes efficiency

- Reduces rinse cycles and regeneration

- Increase regeneration efficiencies to theoretical values

-

SS slotted wedge-wire distributor design

w/slot size options ranging from 0.008 to 0.015 - Proprietary design for improved flow control

- Application in process vessel, retrofit / replacement internals (header & lateral distributors)

AWTS Resin Trap Design Features & Options include:

-

Stainless steel housings w/ANSI flanges or

-

Clear-acrylic housings w/Sch 80 PVC flanges

-

Sight glass assembly for SS housing

w/ optional 250º F temperature rating -

Media / Resin removal valve

-

Additional ports for instruments and gauges

- SS wedge-wire

strainer basket

w/slot size options ranging from 0.008 to 0.015 - PVC, PPL, or PVDF

strainer basket material

w/plastic mesh sleeve optional - Pipe sizes from 2" to 8" inside diameter

- Application in retrofit or new equipment

Articles

by Ken Pandya:

Water Reuse, Microelectronics, and

more.

- "Ion-Exchange

Demineralizers, Big Problems, Small Solutions"

Presented to the 58th Annual Meeting, International Water Conference,

Pittsburgh, PA - "Microelectronics -

Lessons learned: The installation of a 300 to 600 GPM Semiconductor

High Purity Water System.

Appeared in Ultrapure Water Journal, USA - "Water

Reuse - The Award Winning Reclaim System

at Philips Semiconductor's San Antonio Wafer Fab.

Appeared in Ultrapure Water Journal, USA

Author: Ken Pandya, the president of AWTS INC is author and co author of technical articles appearing in the Ultra pure Water Journal from 1999 to 2003, and in other trade publications of the water treatment industry. Under his leadership, the company has specialized in water treatment retrofits, upgrades, and development of specifications for high-purity water and waste recycle systems.

Mr. Pandya serves on the American Society of Mechanical Engineers, Research Committee on Power Plant and Environmental Chemistry.